QuRan Machinery

Top, Professional and Reliable Manufacturer of Various Machinery

Email:quranmachinesales01@gmail.comPhone/Wechat/WhatsApp:+8618203796120

OTHER MACHINERY>>Gantry shearing machine

CONTACT US

Tel/Wechat: +86 18203796120

WhatsApp:+86 18203796120

Email:quranmachinesales01@gmail.com

Send Inquiry

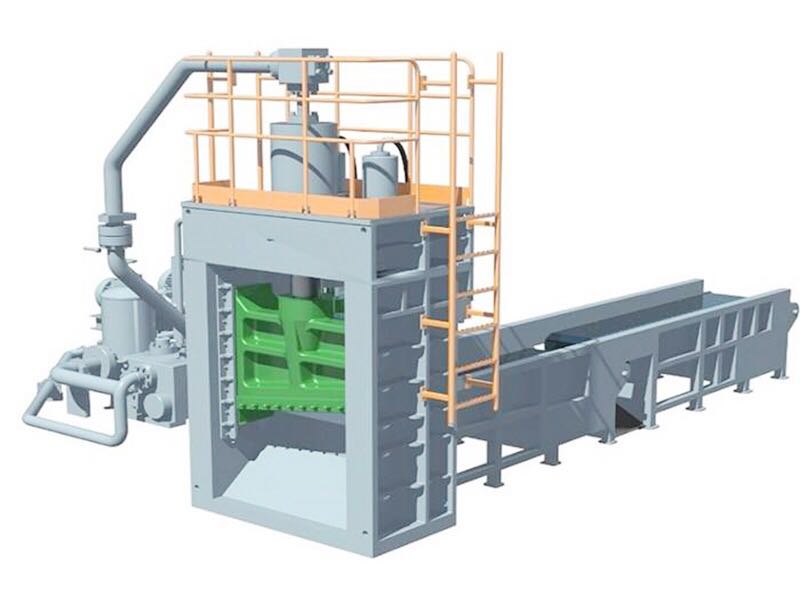

Gantry shearing machine

Gantry shears, also known as gantry shears, are mainly used to compress and pack all kinds of solid scrap iron, heavy scrap, light scrap steel, reinforcing steel, metal blocks, scrap car shells, light metal structural large pieces made of steel, profiles, scrap steel for production and life, plastic non-ferrous metals (stainless steel, aluminium alloy, copper, etc.) and cut them to meet the applicable specifications of furnace materials. They are rolling mills and non-ferrous metals. Ideal equipment for metal smelting industry, precision casting industry and raw material manufacturers. The gantry shear is composed of frame, hydraulic cylinder, hydraulic power system and electrical system. In principle, the scrap is automatically sent to the cutting edge by the conveyor belt after the material is grabbed into the feeding box. The feeding speed can be adjusted by the speed regulating motor. Side extrusion cylinders are installed on both sides of the tank. Large waste materials, such as scrap cars, can not be cut through the gantry scissors. The waste can be squeezed and reduced through the side extrusion cylinder, and then sent to the cutting edge through the conveyor to cutoff.

Features of Gantry shearing machine:

1. The scrap steel shaping and segmented feeding method with upper compression and side compression are adopted, and the design of the wide material box is adopted, so it has good applicability to scrap raw materials and high compactness after shearing.

2. The opening area of the material box is large, which is suitable for machining materials, loose heavy waste, light and thin scrap steel, automobile shells, large irregular light steel structural parts, steel pipes, steel plates, channel steel, I-beam, steel bars and other profiles. , easily put into the material box, fully amplifying the utilization rate of the equipment.

3. Adopt PLC automatic control touch screen control panel automatic integrated control, and multi-angle whole-process monitoring system, which is convenient for users to control and track the use of equipment throughout the process. The operation is stable and reliable, and the wireless remote control device is optional, and a single person can operate the supporting equipment of the production line.

4. Adopt reliable large flow logic valve control, independent filtration and cooling system to ensure efficient and stable operation of the system. The comprehensive application of constant power variable and differential fast technology can save about 30% while ensuring the output, and the energy consumption per ton of scrap steel processing is lower than the requirements of the same industry standard.

The main technical parameters:

| Model | Maximum shear force | Boxes size | Knife length | Productivity | Shear frequency | Main motor power |

| QR400W | 400T | 6000*1400*800mm | 1400mm | 8-10T/h | 4/min | 37kw*2 |

| QR630W | 630T | 8000*1800*900mm | 1800mm | 12-15T/h | 4/min | 45kw*2 |

| QR800W | 800T | 8000*2000*900mm | 2000mm | 15-20T/h | 4-5/min | 45kw*3 |

| QR1000W | 1000T | 8000*2000*1200mm | 2000mm | 18-25T/h | 4-5/min | 45kw*4 |

| QR1250W | 1250T | 10000*2000*1400mm | 2000mm | 25-30T/h | 4-5/min | 45kw*5 |

Maintenance

1. Operate in strict accordance with the operating procedures.

2. Add lubricating oil regularly, fixed-point and quantitatively according to the requirements of the lubrication chart before each startup. The oil should be clean and free of precipitation.

3. The equipment must be kept clean frequently, and the unpainted part must be kept clean with anti-rust grease.

4. The lubricating oil in the motor bearing should be replaced and refilled regularly, and the electrical parts should be checked regularly to see if they are normal, safe and reliable.

5. Regularly check whether the oil cylinder, handle, knob and button are damaged. If the wear is serious, it should be replaced in time and reported for spare parts.

ZhengZhou Quran Machinery Co. , Ltd.

QuRan WeChat

QuRan WhatsApp

Email:quranmachinesales01@gmail.com

Phone/Wechat/WhatsApp:+8618203796120

Copyright © 2022 ZhengZhou Quran Machinery Co. , Ltd.