QuRan Machinery

Top, Professional and Reliable Manufacturer of Various Machinery

Email:quranmachinesales01@gmail.comPhone/Wechat/WhatsApp:+8618203796120

Fiber separator

CONTACT US

Tel/Wechat: +86 18203796120

WhatsApp:+86 18203796120

Email:quranmachinesales01@gmail.com

Send Inquiry

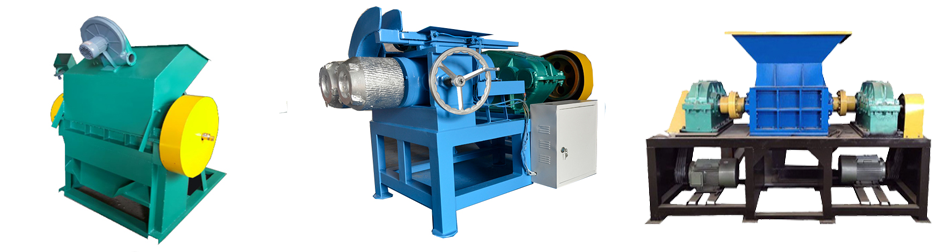

Fiber separator

The fiber separator is different from the general cyclone fiber separator, and the two machines have different shapes and structures.

more different. Its function is mainly to disintegrate the rubber particles pulverized by the pulverizer, and the fine particles mixed in the rubber powder.

The fluff fibers are separated to improve the purity of the rubber powder, thereby improving the quality of the reclaimed rubber product.

A transmission device is arranged in the center of the body, and the impeller is installed on the main shaft of the transmission device.

The blades are connected into one body and rotate with the main shaft. The main shaft drives the impeller to rotate at high speed with fine fluff

The fiber rubber particles and rubber powder enter the body, and the impellers on both sides of the body rotate rapidly to generate air flow. The fine fluff fibers in the powder rise and float,

Under the action of airflow, it is discharged through the guide pipe, and the pure rubber particles and rubber powder cannot float due to their large specific gravity, so they flow out through the screen installed on the base.

Quran Fiber separator

The fiber separator is compact in structure and high in efficiency, which can greatly simplify the process of processing rubber particles and rubber powder.

The main technical parameters:

| Model | Main power | Prodactivity | Weight | Dimensions |

| QRF1000 | 11KW | 1T/H | 1500KG | L1300*W1300*H3500 |

Safety maintenance of Fiber separator

1. The bearing should be lubricated once a week.

2. When installing, pay attention to the verticality of the main body and the level.

3. Configure the power cord and control switch according to the power of the equipment.

4. After installation, check whether the bolts in each part are loose or not.

5. The safety device should be kept in good condition, and it should be checked frequently during the working process. If it is damaged, it should be stopped immediately.

Features of Fiber separator

The working principle of the fiber separator is based on the weight difference between the fine rubber powder obtained in the process of recycling waste tires and the nylon fibers mixed with it. Under the action of airflow, different upward forces are generated, and the rubber powder falls through the hollow shaft On the distribution plate, and then thrown into the air guide cone, the fan blades and small fan blades rotate at high speed to generate upward airflow, so that the wind pressure near the fan blades is lower than the wind pressure around the distribution plate. In this way, the fine fluff fibers in the rubber powder rise and float, and when they reach the fuselage wall, they fall along the surface of the bottom cover of the fuselage wall, and then are discharged from the outlet of the cone end of the bottom cover. Can not float, the eye deflector falls into the cone and is discharged from the discharge pipe, thus completing the purpose of separating fibers. From the appearance of the separator, the upper section is a cylinder, and the lower section is a cone. In order to facilitate disassembly and assembly , The cover and the upper section, the upper section and the lower section are all connected by screws. The main shaft of the separator is a hollow body. In the sleeve seat at the lower end of the main shaft, two single-row radial spherical bearings are installed, and the upper end is sleeved with a one-way thrust Bearings are used to support the rotation of the main shaft. The main shaft is connected with the fan blade, the fan blade plate and the powder distribution box, and rotates together with the main shaft. In the fuselage, it is welded to the circular windshield through four support plates. The wind guide cone cover and the wind guide cover are connected to the wind cover. The conical discharge hopper is supported by four centering blocks in the bottom cover of the lower section, and a pipe is welded at the bottom of the discharge hopper, which is the outlet of the rubber powder. The angle between the center line and the center line is 30°, and a baffle is welded on the circumference of the upper end of the discharge hopper, and the cone end of the lower bottom cover is the fiber outlet.

ZhengZhou Quran Machinery Co. , Ltd.

QuRan WeChat

QuRan WhatsApp

Email:quranmachinesales01@gmail.com

Phone/Wechat/WhatsApp:+8618203796120

Copyright © 2022 ZhengZhou Quran Machinery Co. , Ltd.