QuRan Machinery

Top, Professional and Reliable Manufacturer of Various Machinery

Email:quranmachinesales01@gmail.comPhone/Wechat/WhatsApp:+8618203796120

Steel wire separator

CONTACT US

Tel/Wechat: +86 18203796120

WhatsApp:+86 18203796120

Email:quranmachinesales01@gmail.com

Send Inquiry

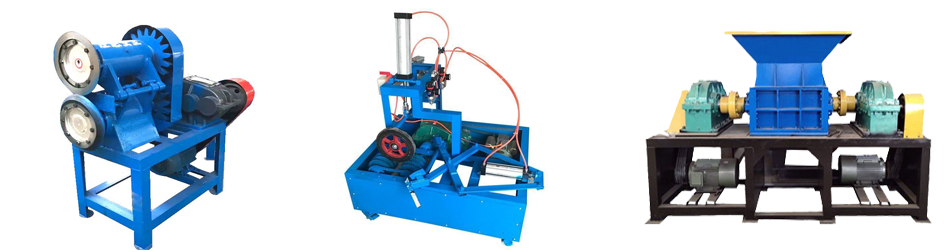

Steel wire separator

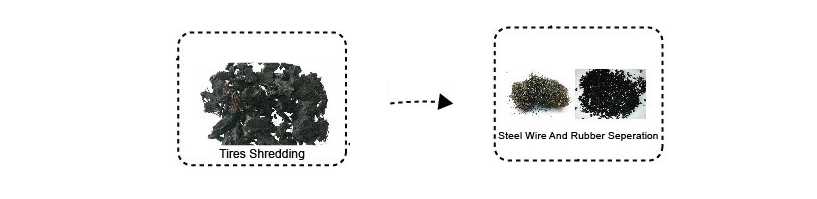

The rubber block within 100mmx100mm is processed into 10-15mm rubber particles, and the steel Filament and rubber separation. The waste steel wire radial tire is separated from the rubber steel wire by the whole tire crusher. The new type relates to a rubber-steel-rubber-steel rubber-steel-rubber-rubber block crushed by a whole tire crusher for waste steel wire radial tires. It is an important equipment for wire separation and crushing machinery. This model is that the cutter head of the movable knife and the cutter head of the fixed knife are rectangular, and the cutter head of the movable knife adopts High hardness tungsten carbide is welded on the base of the fixed knife. Due to the use of high wear-resistant materials in the wearing parts of the rubber wire separator, the durability of the tool is improved when separating and crushing rubber blocks. Grinding, prolonging the service life of the rubber wire separator.

Quran Steel wire separator

The feed is 100mmx 100mm rubber block, the output is 10=15mm rubber granules, the single machine output is 400-4000kg/h.The rubber block with steel wire can be processed into rubber particles, and the steel wire and rubber can be separated at the same time. Due to the special design of the moving knife and the fixed knife, the machine has high working efficiency, The tool has stronger rigidity, higher wear resistance and longer service life.

The main technical parameters:

| Model | Main power | Prodactivity | Inlet size | Dimensions | Weight |

| HNSC600 | 30KW | 300KG/H | 600*400mm | L2700*W900*H2500 | 2000KG |

| HNSC800 | 55KW | 600KG/H | 850*400mm | L3100*W1000*H2600 | 3000KG |

| HNSC1000 | 132KW | 1000KG/H | <1000*550mm | L3500*W1100*H2600 | 4500KG |

| HNSC1200 | 132KW | 1000KG/H | <1200*600mm | L4000*W2500*H400 | 5500KG |

Fundamental of Quran's Steel wire separator

The tire wire separator adopts a reducer to drive the cutter roller, which runs smoothly and has little vibration; the box body is integrally processed by a high-precision CNC machining center to ensure that the equipment can run smoothly under high load for a long time and prolong the service life of the transmission parts; The wear-resistant steel plate greatly improves the overall wear resistance and effectively reduces the maintenance cycle and maintenance cost; the main shaft is made of high-strength alloy steel, and the overall quenching and tempering treatment ensures that the equipment can run under high load for a long time; the tools can be independently disassembled and installed, which can be used for short-term The time is quickly disassembled, which improves the production continuity; the fixed knife can be repaired and used repeatedly, with good interchangeability and long service life; the blade gap can be adjusted according to the type and thickness of the material, which is convenient to achieve good crushing effect; upper and lower chassis The hinged connection is opened or closed by hydraulic pressure, which greatly facilitates the inspection and maintenance of the knife roller; the screen is opened or closed by hydraulic drive, which can be quickly replaced and maintained.

Advantage of Steel wire separator

1. The new overall structure design of crushing and separation makes the equipment take up less space.

2. The novel plate screening structure makes screening more convenient and clean.

3. The use of wear-resistant materials reduces the number of replacements of wearing parts.

4. Lower machine power and lower equipment cost.

5. The crushing and screening effect is ideal.

ZhengZhou Quran Machinery Co. , Ltd.

QuRan WeChat

QuRan WhatsApp

Email:quranmachinesales01@gmail.com

Phone/Wechat/WhatsApp:+8618203796120

Copyright © 2022 ZhengZhou Quran Machinery Co. , Ltd.